An epicyclic gear train (also known as planetary gear) consists of two gears mounted so that the center of one gear revolves around the center of the other. A carrier connects the centers of the two gears and rotates to carry one gear, called the planet gear or planet pinion, around the other, called the sun gear or sun wheel. The planet and sun gears mesh so that their pitch circles roll without slip. A point on the pitch circle of the planet gear traces an epicycloid curve. In this simplified case, the sun gear is fixed and the planetary gear(s) roll around the sun gear.

An epicyclic gear train can be assembled so the planet gear rolls on the inside of the pitch circle of a fixed, outer gear ring, or ring gear, sometimes called an annular gear. In this case, the curve traced by a point on the pitch circle of the planet is a hypocycloid.

The combination of epicycle gear trains with a planet engaging both a sun gear and a ring gear is called a planetary gear train. In this case, the ring gear is usually fixed and the sun gear is driven.

Epicyclic gears get their name from their earliest application, which was the modelling of the movements of the planets in the heavens. Believing the planets, as everything in the heavens, to be perfect, they could only travel in perfect circles, but their motions as viewed from Earth could not be reconciled with circular motion.

Planetary gearing is a gear system consisting of one or more outer, or planet, gears or pinions, revolving about a central sun gear or sun wheel. Typically, the planet gears are mounted on a movable arm or carrier, which itself may rotate relative to the sun gear. Epicyclic gearing systems also incorporate the use of an outer ring gear or annulus, which meshes with the planet gears. Planetary gears (or epicyclic gears) are typically classified as simple or compound planetary gears. Simple planetary gears have one sun, one ring, one carrier, and one planet set. Compound planetary gears involve one or more of the following three types of structures: meshed-planet (there are at least two more planets in mesh with each other in each planet train), stepped-planet (there exists a shaft connection between two planets in each planet train), and multi-stage structures (the system contains two or more planet sets). Compared to simple planetary gears, compound planetary gears have the advantages of larger reduction ratio, higher torque-to-weight ratio, and more flexible configurations.

The axes of all gears are usually parallel, but for special cases like pencil sharpeners and differentials, they can be placed at an angle, introducing elements of bevel gear (see below). Further, the sun, planet carrier and ring axes are usually coaxial.

Epicyclic gearing is also available which consists of a sun, a carrier, and two planets which mesh with each other. One planet meshes with the sun gear, while the second planet meshes with the ring gear. For this case, when the carrier is fixed, the ring gear rotates in the same direction as the sun gear, thus providing a reversal in direction compared to standard epicyclic gearing.

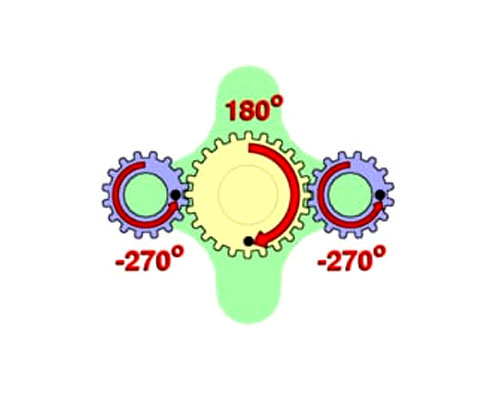

In this example, the carrier (green) is held stationary while the sun gear (yellow) is used as input. Analysis assumes a common gear design modulus. The planet gears (blue) turn in a ratio determined by the number of teeth in each gear. Here, the ratio is −24/16, or −3/2; each planet gear turns at 3/2 the rate of the sun gear, in the opposite direction.

Planetary gears have become popular in 3D printing for a few different reasons. Planetary gear boxes can provide a large gear ratio in a small, light-weight package. Some people install such gearboxes to get more accurate 3D prints by gearing-down the movement of their stepper motors.

A geared-down motor must turn farther and faster in order to produce the same output movement in the 3D printer—and that is a good thing. If the stepper motor has to turn farther then it also has to take more steps to move the printer a given distance; therefore, the geared-down stepper motor has a smaller minimum step-size than the same stepper motor without a gearbox. While there are many involved factors, planetary gearboxes may help produce very high quality 3D prints.

One popular use of 3D printed planetary gear systems is as toys for children. Since herringbone gears are easy to 3D print, it has become very popular to 3D print a moving herringbone planetary gear system for teaching children how gears work. An advantage of herringbone gears is that they don't fall out of the ring and don't need a mounting plate.

Planetary gear trains provide high power density in comparison to standard parallel axis gear trains. They provide a reduction in volume, multiple kinematic combinations, purely torsional reactions, and coaxial shafting. Disadvantages include high bearing loads, constant lubrication requirements, inaccessibility, and design complexity.

The efficiency loss in a planetary gear train is typically about 3% per stage.[15] This type of efficiency ensures that a high proportion (about 97%) of the energy being input is transmitted through the gearbox, rather than being wasted on mechanical losses inside the gearbox.

The load in a planetary gear train is shared among multiple planets; therefore, torque capability is greatly increased. The more planets in the system, the greater the load ability and the higher the torque density.

The planetary gear train also provides stability due to an even distribution of mass and increased rotational stiffness. Torque applied radially onto the gears of a planetary gear train is transferred radially by the gear, without lateral pressure on the gear teeth.

In a typical application, the drive power connects to the sun gear. The sun gear then drives the planetary gears assembled with the external gear ring to operate. The whole set of planetary gear system revolves on its own axis and along the external gear ring where the output shaft connected to the planetary carrier achieves the goal of speed reduction. A higher reduction ratio can be achieved by doubling the multiple staged gears and planetary gears.

The method of motion of a planetary gear structure is different from traditional parallel gears. Traditional gears rely on a small number of contact points between two gears to transfer the driving force. In this case, all the loading is concentrated on a few contacting surfaces, making the gears wear quickly and sometimes crack. But the planetary speed reducer has multiple gear contacting surfaces with a larger area that can distribute the loading evenly around the central axis. Multiple gear surfaces share the load, including any instantaneous impact loading, evenly, which make them more resistant to damage from higher torque. The housing and bearing parts are also less likely to be damaged and crack from high loading.